Fluorescent Dissolved Oxygen Sensors

Maintaining the proper concentration of dissolved oxygen (DO), in an aeration basin is necessary to keep microorganisms alive for the breakdown of organic waste. DO levels must be precisely monitored so a treatment facility stays in compliance with regulatory discharge standards and to protect the environment.

In addition, aeration in wastewater treatment also accounts for approximately 60% or more of the total energy consumption in wastewater treatment plants. Plants that aerate constantly will probably maintain a higher DO level than necessary, which wastes money and energy with blowers operating full time. Monitoring of dissolved oxygen will allow the cycling of blowers to operate only when dissolved oxygen is needed thereby saving substantial energy costs.

This can only be accomplished by using an accurate, continuous dissolved oxygen monitoring system.

Aysix Technologies optical fluorescence dissolved oxygen sensors and analyzers help control energy costs in aeration control. Aysix dissolved oxygen sensors utilizes an optical technique that does not consume oxygen like all standard membrane sensors, have no membranes, no fill solutions and no consumable spare parts, require no routine calibration or maintenance, have a provision for air jet automatic self cleaning and best of all, has an industry leading 5 year guarantee.

Total suspended solids sensors

Measuring suspended solids in water is used for control of various treatment processes and for examination of wastewater quality. Measuring suspended solids using a TSS sensor allows for instantaneous monitoring and control of the process where the sensor is installed. Suspended solids measurements may be useful in any process where suspended solids are present or are removed, such as coagulation and flocculation, settling, clarification, precipitation, and filtration.

Aysix Technologies Suspended Solids Instruments provide solutions for measuring solids in municipal wastewater and industrial process applications. Instruments feature self-cleaning options and unique technology to improve the precision and accuracy of measurements and options for use within hazardous zones.

Analyzers and controllers

Aysix analyzers are compatible with all Aysix water quality sensors. Analyzers are available in 1, 2, 4, multi channel, multi sensor as well as wirleess configurations.

Chlorine analyzers

Chlorine analyzers are used to control disinfectant chemical feed in drinking or wastewater, industrial process water and to monitor the drinking water distribution system. Available in four models; Free, total, and Chlorine Dioxide

Wireless transmission of DO, TSS, PH, ORP

Aysix wireless water quality sensors will wirelessly connect any 20 Series sensor with the Process Transmitter (PT 2). Compatible sensors include DO, SS, pH, and ORP sensors. The 20 Series system allows for flexible and economical process monitoring and control. The ST 2 has an outdoor line of sight range of up to 1500 feet. If the PT 2 is mounted indoors, the closest ST 2 should be within 600 feet. The ST 2 links together with other ST 2’s and the host PT 2 to form a ZigBee compliant RF network with self-healing mesh technology ensuring trouble-free communications. This significantly reduces installation costs as the there is no need for interconnecting cable or conduit.

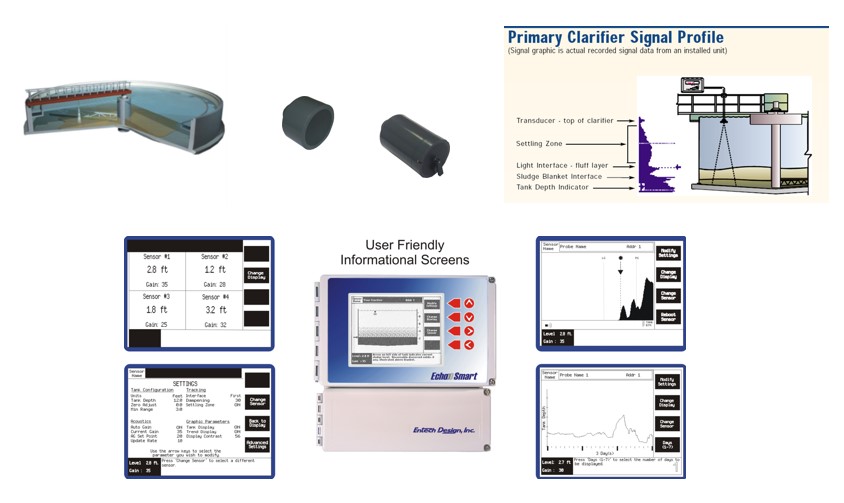

Blanket level measurement

The continuous measurement of sludge levels in both primary and secondary sedimentation tanks allows sludge extraction pumps to be used efficiently, whilst ensuring poorly settled sludge does not carry over into effluent paths. However, for these advanced systems to work effectively, one of the most crucial parameters for plant operators to monitor is the total solids, or sludge, as it moves through the plant.

The Aysix EchoSmart, is designed for superior sludge level detection and measurement in a wide range of water and wastewater applications.

Wastewater samplers

There are multiple reasons for sampling water or wastewater. Often it is a legally required, and it helps to protect surface water, to monitor wastewater treatment processes or to identify dischargers into a sewage system. Our automatic water samplers are the smart and proven way of sampling. The fully automated systems take samples for industrial and municipal wastewater treatment plants, water management authorities and all industrial customers where reliable water sampling is required..

Incorporated within every one of our samplers is the unique Aquacell Sampling Module, a wide-bore vacuum pump sampling system. This high performance vacuum pump sampling module provides reliable and repeatable extraction of truly representative samples from your wastewater source.

Septage Receiving Systems

Many wastewater treatment plants and private liquid waste processing facilities handle septage before it enters the treatment process, using a septage receiving system. Septage receiving systems provide an automated solution for receiving, treating & monitoring waste from septic tankers. The system allows easy pass key access for approved septic haulers to discharge truck loads while offering plant operators simple security, transaction recording and process monitoring. Each system is custom designed to account for varying communication, data collection, and treatment requirements.

Cellular cloud base telemetry systems

Mission Communication managed SCADA telemetry systems is simply a better approach to monitoring processes, collecting data, notifying users of alarms and creating automatic reports. Traditional SCADA for water/wastewater requires users to build their own proprietary system. That means going through the specification and bidding process, then managing the engineering, construction, and debugging of a new technology.

Mission remote terminal units (RTUs) are very simple to operate and designed for the specific purpose of water/wastewater monitoring. By including only the necessary features in a single package, Mission is able to keep the cost low, minimize security vulnerabilities, simplify installation, and maximize reliability.

Not required are maintenance and license fees that spiral up year after year, complicated radio path studies, antenna towers, network maintenance and vulnerable and expensive phone or fiber lines that are easy to cut and complicated to repair

Many of the flowmeters that we supply have been used in a variety of flow measurement applications in the Water and Wastewater industry.

The ALMAG WP is a conventional magnetic flowmeter used to measure flows of water, waste water and other conductive liquids in full pipes.

The ALMAG PF is an electromagnetic flowmeter for partially filled pipes. It has several sets of electrodes for measuring fluid velocities in different locations as well as an integrated level sensor to produce very accurate and continuous area velocity flow measurement.

The ALMAG IS is a robust insertion type electromagnetic flowmeter made to measure flows of water, wastewater and other conductive fluids in very large pipes.

The Alsonic SAVM is a transit time flowmeter for measuring the flow of water and wastewater (< 30% suspended particles) in partially filled or fully filled pipes. Up to 4 pairs of flow velocity sensors are distributed over the bottom half of the flow tube to provide precise flow values when the pipe is partially or completely filled. The Alsonic SAVM is easily installed in partially filled pipes, sewer inlet/outlet pipes as well as other open channel applications.

The ALSONIC DAVM is a Doppler flowmeter for measuring liquids that are highly charged with suspended solids. The DAVM flowmeter features an ultrasonic Doppler transducer with an integrated piezo sensor, enabling it to measure both liquid velocity and level with a single sensor.

The Aysix Stebatec LDM flowmeter is a transit time calibrated flowmeter for measuring the flow of wastewater in partially filled or fully filled pipes. Ten flow velocity measurement sections are distributed over the entire cross-section of the flow tube to provide precise flow values when the pipe is partially or completely filled. Level measurement of the pipe being measured is integrated into the flow meter assembly.

Please contact us at controls@cancoppas.com or call us at the appropriate office should you require additional assistance.

Contact Us