All D3 models feature a zero-bleed pneumatic relay, suitable for linear or rotary valves, single- or double-acting actuators, and special applications; all featuring the same easy-to use user interface for local configuration with Communication via HART®, Profibus PA and DP, Foundation Fieldbus and Wireless ISA100™ is possible.

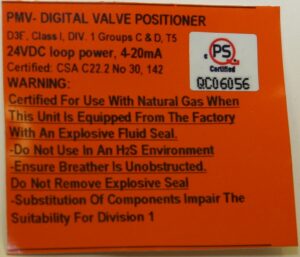

D3E hazardous area explosion proof is multi approval rated:

ATEX: II 2G Ex d IIB+H2 T6 Gb (-20°C to +60 °C) II 2D Ex tb IIIC T100°C Db (-20°C to +80°C)

CSA, FM: Class I, Div.1 Grps B, C, D Class II, Div.1 Grps E, F, G Class III, Div.1 T6, T5 / Type 4X

Being that the D3 positioner is extremely low air/energy consumption – zero bleed – it meets the EPA 6.0 SCFH leak limit standard, hence can use NG as supply medium. The D3E has been approved to CSA standard for use on natural gas, when configured with the required ancillary components. This configuration done by us in our plant, following which each positioner being inspected and certified to CAN/CSA C22.2 No. 30-2020

CONTACT US for more information, or a quote, on the D3E gas approved positioner

For more information on the D3 as well as our other positioners :Valve Control

Download D3E CSA EXP Certificate

Series PTS02 is a Programmable Temperature Switch & Transmitter offering an analog 4-20 mA output, transistor or relay switch output, and an optional RTD output. Utilizing patented MIST technology, PTS02 is designed for optimum accuracy and performance. Shipped factory calibrated to customer specified temperature ranges. Unique feature of the PTS02 is that it is re-programmable. Process temperature or alarm change? No problem! Calibration is password protected using the PTS02-PKIT interface module and re-range your PTS without the need to recalibrate and without the loss of accuracy. When it is re-scaled to a different temperature range, the calibrated default values are not lost. This transducer can be re-calibrated by performing one-point or two-point calibration using known temperature standards. This is where the PTS02 leaves the competition behind. Indicating temperature range, current output, switch set point, switching hysteresis, switch logic, damping and other features are all programmable.

The PTS02 wetted parts, as well as the housing, are fabricated from 316 stainless construction. Other materials, various probe diameters, fitting sizes and thermowell types are available. For electrical connection, a 1/2” NPT conduit with lead wires is standard. The sensing element used is Pt-100 Ohm RTD Class A. PTS02 can be made available with an additional 3-wire RTD output. This feature allows a single process connection to be used for indication of temperature and for remote indication, recording, or controlling. Each PTS02 has the part number, range and serial number marked on the transmitter housing.

This product is protected under US patent 7,223,014 and CDN patent 2,561,570.

Solutions include : Encoders – Positioners – Thermal Mass Flow meters

The PMV D3E is a CSA approved Non Incendive – CL I, Div 2, Groups A,B,C,D, Intrinsically Safe – CL I, Div 1, Groups A,B,C,D approved digital and SMART positioner.

The D3E explosion proof digital positioner is supplied in a die-cast housing is treated with a powder epoxy, protecting the unit from corrosion and mechanical damage. The D3ENE is an all 316 SS explosion proof positioner and is ideal for very corrosive environments, off shore applications and is of a marine grade design.

DTM-Valve-Sight is an optional feature that provides the D3 digital positioner with optional on-board pressure sensors with unique diagnostic capabilities. The DTM is available for free download, which includes Advance Diagnostic DTM, as e.g. Step- and Ramp tests.

Other features and options include failfreeze on loss of signal, profibus and foundation fieldbus protocols.

For valve control we offer the D3 positioner in Explosion proof versions :

Our listing of positioners can be found here: PMV Positioners

Aysix Sage Thermal Mass flow meters are precisely factory calibrated to a single or several different gas percentage components. These meters have no moving parts, provide gas mass flow rate, and repeatable, reproducible, and reliable flow measurements. Measuring not only common gases from Ammonia to Propane, BioGas, BioMethane, to Flue and Flare gas. Thermal Mass Flow meters

Explosion proof Encoders from BEI are available as Absolute and Incremental :

download the complete listing BEI Complete catalogue

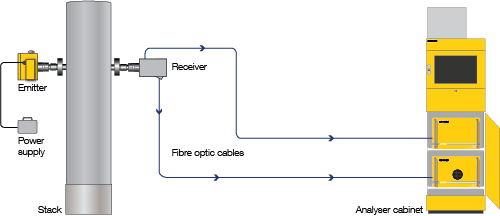

OPSIS is a global supplier of environmental monitoring systems for gas analysis and related services. Systems are calibrated to either single or multiple gas parameters and use Differential Optical Absorption Spectroscopy (DOAS) Additional gas compounds that need to be measured can usually be added in the field without returning the system. Since monitoring is done by DOAS, and not extraction of gases, resulting measurements are in real time.

The OPSIS DOAS system is different and provides chemical plants with an accurate analyser that will operate with a minimum of maintenance. The OPSIS DOAS system is based on a non-contact method using an optical measurement path that can operate across the duct.

The optical light is transported in an optical fibre to the analyser and one analyser can operate several paths.

A number of systems are available to monitor various environments. Open Path Fenceline Gas Detection, which monitors the perimeter, known as Fence-line monitoring using an open-path monitoring system is an excellent tool for monitoring the air quality, as well as fugitive emissions and gas leaks.

Of critical importance is the real-time monitoring of fugitive emissions from oil refineries, is Benzene, known as Benzene Fence line Monitoring

A basic system includes an analyser, an emitter/receiver set, and an optical fibre cable.

For a complete listing of OPSIS systems as well as videos, visit the OPSIS site : OPSIS Monitoring systems

Link to the OPSIS article called What’s Going on in the Air at Chemical Industries?

Link is for a variety of short informational videos found on the OPSIS website : OPSIS Play

Measuring benzene emissions from a refinery plant can be challenging, but OPSIS makes it easy.

REQUIREMENTS FOR BENZENE MEASUREMENT

Benzene is a liquid hydrocarbon that evaporates rapidly when exposed to ambient air. It is one of the more common substances used in the chemical industry and is particularly prevalent at refineries and similar operations. Benzene causes cancer and is therefore subject to monitoring.

MEASUREMENT WITH OPSIS CERTIFIED SYSTEMS

Benzene concentrations can be measured with high accuracy in real time using the OPSIS UV-DOAS systems. The DOAS technology uses optical beams to measure gas concentrations. By placing monitoring paths around a refinery, emissions and leaks can be detected easily and reliably. The monitoring paths form a kind of fence around the plant and the method is an example of so-called fence-line measurement. By combining concentration data with meteorological information, it is possible to calculate the location of emission sources and the flow of benzene emissions.

The OPSIS UV-DOAS system is designed for long-term, continuous use. Maintenance requirements for the OPSIS DOAS systems are minimal. According to U.S. EPA regulations, the instrument only needs to be calibrated with reference gas once every three months.

AIR POLLUTION MONITORING WITH OPSIS

There are multiple reasons for choosing OPSIS as supplier of systems for gas analysis. Among the key benefits of the methods and solutions offered by OPSIS are:

Links to OPSIS videos :

Link to the OPSIS article called What’s Going on in the Air at Chemical Industries?

Sales is restricted to the province of Quebec and the Maritime Provinces

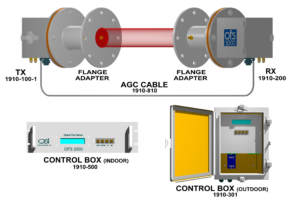

The optical scintillation technique uses measurements of turbulence movements found in the emission gas flow stream to give highly accurate measurements of mean path air velocity.

– Uses optical scintillation principle compliant with EPA Method 14 and traceable to NIST

– Non-intrusive, non-contact method, with no direct exposure to gases emitted by stacks or processes

– Measures stacks from 0.5 to 10 meters in diameter

– Conditions such as temperature, pressure, gas composition, vapors, densities, dust or humidity do not compromise flowmeter accuracy or operation

– Operates with emissions and gases up to 95% opacity.

– Very simple installation

– Very low maintenance

– Can be isolated by a knife gate valve

– Unaffected by non-uniform flow velocity profiles caused by elbows, transition ducts, valves and other obstructions.

Flow Performance

Measurement Technique : Optical Scintillation (OSi Patented)

Dynamic Range : 0.03 to 100 m/sec, bidirectional (higher rates possible on RS-232 port)

Accuracy (absolute) : +/- 0.01 m/sec basic -or- +/- 2% of reading, whichever is greater

Repeatability (relative) : +/- 0.01 m/sec basic -or- +/- 1% of reading, whichever is greater

Long Term Drift : Less than 1% per year

Time Constant(s) : Response 0.3 sec., Update: 3 sec., Averaging (selectable): 3 to 600 sec.

Automatic Calibration : 2 or 3 point; user selectable interval -or- on external command

Sensor Health Monitoring : Continuous self-test of voltages, performance, optics, etc.

Media / Environmental

Stack / Duct / Pipe Diameter : 0.3 to 10 m, standard — consult factory for other ranges

Media Temperature / Pressure / Humidity : No effect on measurement

Media Transparency : Up to 95% opacity (OFS-2000-FW recommended for high opacity)

Ambient Temperature / Humidity : -50 to 60 C (-58 to 140 F) / 0 – 100% condensing

Physical Specifications

Light Source :Eye-safe 670 nm visible red LED, 5 deg. divergence angle

Sensor Heads (w/ 4” sch.40 flange extender) : 9 x 9 x 13 inches, 13 lbs. — NEMA4 weather resistant

Control Unit: Rack Mount Version (standard) :

NEMA4 Wall Mount (optional) : 5 x 17 x 20 inches, 13 lbs. (for indoor use) 12 x 16 x 10 inches, 15 lbs. (for outdoor / factory floor use)

Electrical Specification

User Interface : RS-232 serial I/O and / or 4-20 mA optically isolated current loop; Also two sets of relay contacts for fault and calibration indication.

Power for Transmit Head : Universal 100-240 VAC, 50/60 Hz, 12 VA (fused & surge protection)

Power for Control Unit : Universal 100-240 VAC, 50/60 Hz, 40 VA (fused & surge protection)

Cable between Control Unit & Receive Head : 15 foot standard; to 300 foot optional (shielded, 10 cond., 22 AWG)

Links to videos on the OSPSIS website will open in a new tab

Please contact us at controls@cancoppas.com or call us at the appropriate office should you require additional assistance.

Contact Us