Building materials encompasses a wide variety of materials, with each having a different solution.

Not sure what is the best solution for your needs, simply contact us using our form, we will be happy to provide the best options based on your application and needs,

Some applications require only knowing when level is full, empty or somewhere in between, may benefit from simple solutions to detect level.

If your needs are a simple contact output to trigger an operation to start or stop filling or to a horn or other visual indication.

Choosing the right Level Sensor Technology for you. BinMaster level sensor technology guide

The diaphragm switch is for side mounting, while the Rotary unit can be installed as side mount or top mounting with flexible rods, or cables in varying lengths as well as a fully adjustable length which allows for adjustment for exact placement. If space is limited, then our mini-rotary my be what you need. Other level probes available are a vibrating rod, vibrating fork or vibrating probe style can be used.

Level switch types

In some case it is not level that matters but rather if product is flowing or not to indicate a possible plugged chute. Then the FD2000 Flow / No flow microwave level detector is what you need.

If your application requires knowing the exact level at timed intervals, or even constant readings, then you will benefit from the mechanical YoYo , with its timed interval or instant level readings withe several options depending on the application and material. The choices range from capacitance, to laser to radar level sensors, with remote inventory management software appropriate for your application. ( refer to the individual products for their applicable software’s)

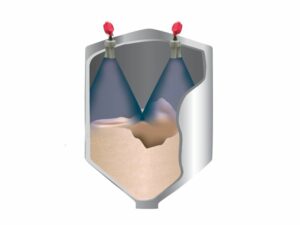

For very large silos, such as cement plants, a more detailed indication of not only level, but 3D mapping is available to give an accurate inventory taking into account buildup, cone up or down conditions.

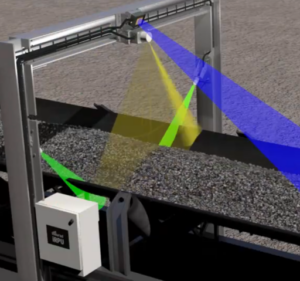

Measuring volume on conveyor belts : traditional methods rely on belt scales that must be calibrated at least annually which means stopping production. A far more accurate system, called iBelt, not only gives you volume measurement, but will alert you when product is off center, overfilled, or even a misalignment of the belt which can lead to premature wear and tear, thus giving you ample warning for preventative maintenance. Your application is for stockpile measurement? Then consider the iStockpile system.

For complete details on iBelt and iStockpile systems as well as several videos click the link below

iBelt and iStockpile Volume Measurement systems

Have a silo, tank or vessel that needs more than just level measurement? Looking to know how much volume you have before you run out of product? Then SiloWeigh is your solution!

Please contact us at controls@cancoppas.com or call us at the appropriate office should you require additional assistance.

Contact Us