The smell associated with pulp production originates from different sulfur compounds. The most well-known is probably hydrogen sulfide, H2S (H-S-H) but there are also compounds like methyl mercaptan (CH3-S-H), dimethyl sulfide (CH3-S-CH3), and dimethyl disulfide (CH3-S-S-CH3). These four substances are collectively referred to as “total reduced sulfur”, TRS. Emissions of TRS together with the usual combustion gases SO2 and NOX (NO and NO2) are regulated and often monitored continuously at pulp production facilities.

Regulations on Emissions Monitoring

Within the European Union, the emissions from most industries are controlled by the Industrial Emissions Directive, the IED. This applies also to the pulp and paper industry. Here, the specific requirements on monitoring and emission limits are found in the “PP-BATC”, which reads out as “best available technique conclusions for the production of pulp, paper, and board”.

When it comes to the recovery boiler, there are requirements on continuous emissions monitoring (CEM) of at least NOX, SO2, and TRS, and in some cases also of dust. This may also apply to the lime kiln and to any separate TRS burner.

The OPSIS TRS Monitor

As already noted, TRS is the name of a group of molecules whereof some are relatively complex. TRS can therefore not be measured directly (“in situ”) using the proven OPSIS open-path DOAS technique. Instead, the OPSIS TRS monitoring system is based on extraction of a relatively small flow of flue gas from the duct. In a first step, all SO2 is removed from the gas mixture using a selective scrubber. In a second step, all remaining sulfur compounds, effectively TRS, are transformed into new SO2 by means of a high-temperature converter. By monitoring the resulting SO2 concentration, which is straight-forward using the DOAS technique, the TRS concentration expressed as sulfur can be established.

In the basic configuration, a TRS monitoring system from OPSIS has a single measurement cell and an AR600 gas analyser to measure the SO2 concentration. However, in many cases, also other types of pollutants should be monitored. The basic system is then supplemented with another measurement cell, resulting in a cost-efficient monitoring solution with low maintenance needs. OPSIS also offers CEM systems monitoring H2S only, using a slightly different converter configuration.

The OPSIS TRS systems delivered so far have all been of the type also monitoring other gases and therefore having dual measurement cells. With our cost-effective, low-maintenance, multi-component gas monitoring system, we are confident that we offer the best CEM solution on the market for the pulp industry.

Download the following article on :

Link is for a variety of short informational videos found on the OPSIS website : OPSIS Play

Sales is restricted to the province of Quebec and the Maritime Provinces.

Optical Scientific, Inc. (OSI) optical scintillation anemometry offers a non-intrusive, path-integrated method for measuring airflow and emissions in large ducts and open pot room environments. It is ideally suited for high-temperature, dusty, and chemically aggressive conditions. OSI systems deliver real-time data with high resolution, minimal signal degradation, and low maintenance requirements—making them a dependable choice for continuous ventilation and emissions monitoring in very difficult and demanding environments.

For more information refer to our product page: Optical Scintillation

Non-contact Volume flow, Material speed, Bulk & belt position

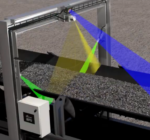

The iBelt system by INDURAD, enhances conveyor operations with high-speed 2D radar scanning for accurate volume flow measurement, capturing cross-sectional views and providing height and material distribution insights. Its radar-based, contactless speed measurement delivers 99% accuracy, optimizing belt speeds and preventing slippage without needing recalibration. The iBelt Misalignment feature detects belt misalignment, reducing wear, energy consumption, and spillage risks. Additionally, its freeboard measurement ensures optimal material positioning, minimizing wear and enhancing belt longevity and safety. Overall, iBelt ensures efficient, safe, and cost-effective material handling.

For detailed information as well as informative videos please click on the link below:

Please contact us at controls@cancoppas.com or call us at the appropriate office should you require additional assistance.

Contact Us