A total of 12 BinMaster 3D level scanners monitoring level in real time were installed on 12 pellet silos.

Installation was by Cancoppas. The 12 silos are connected using a cabled system. The scanners are daisy-chained from 3D Scanner 1 through to Scanner 12, with each scanner terminating to a junction box mounted on the silo railing before being daisy-chained to the next silo.

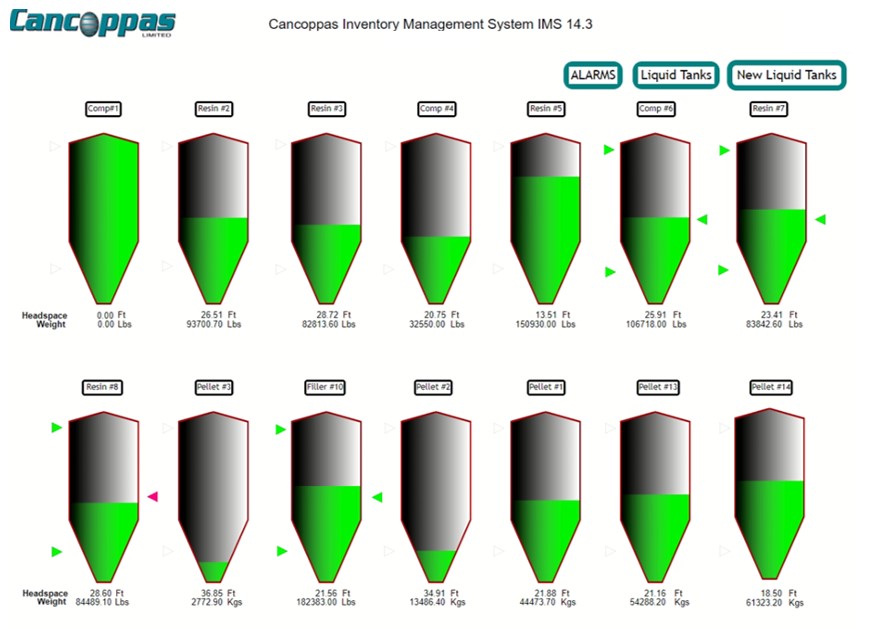

A 21 inch touchscreen display was also supplied. We provided a web-based application developed by Cancoppas, which displays the levels of all silos along with high and low alarm set points. Individual silo / tanks can be viewed with more specific details being displayed such as (Solids) Volume – Bulk Density – High and Low level alarms – Temperature as well as the associated engineering units of measure.

Additional equipment installed were Nivelco’s EasyTek Ultrasonic to measure the liquid level in various tanks.

Information is sent to Nivelco’s MultiCont local controller / display unit. The information was also added to the touchscreen display.

Panel / assembly and wiring by Cancoppas

Nivelco MultiCONT process controller

Please contact us at controls@cancoppas.com or call us at the appropriate office should you require additional assistance.

Contact Us