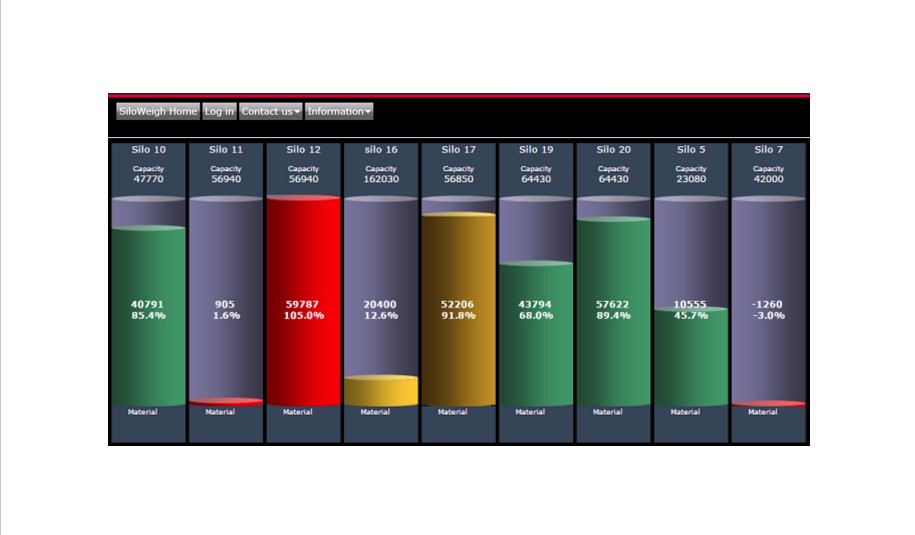

Always know the quantity of material in every silo, tank or storage bin

Never run short of product. Eliminate the risk of overfilling. Check for delivery shortages. SiloWeigh IIoT displays the weight and percentage fill of your silos, storage bins or tanks on your computer or mobile device anywhere and any time, warning you of the need to place an order or prevent an overload of the silo. Accurately measures the actual weight of the contents of the silo to give you a real-time picture of the amount available, together with a history graph, hard-wired alarms, alarm logs and recent readings.

Registered users can view any silo, at any location, through any computer, tablet or smart phone. All silos are displayed with their contents clearly shown as actual weight values, with the ability to show history trend graphs for each silo. Zoom in on any date range. Export data to your Excel files. Check recent alarms.

Use SiloWeigh IIoT to organize your delivery truck schedule. It can send an email to you and your supplier, based on any alarm level.