Advanced Optical Technologies for Emissions and Airflow Monitoring in Aluminum Smelting

Aluminum smelting is a highly energy-intensive process that produces substantial emissions, including hydrogen fluoride (HF), sulfur dioxide (SO₂), and particulate matter. Managing airflow effectively within pot rooms and associated ventilation systems is critical—not only to minimize fugitive emissions, but also to safeguard worker health and maintain process integrity.

Conventional airflow measurement and gas detection techniques often under-perform in the extreme operating conditions of aluminum smelters, where high temperatures, corrosive gases, and heavy particulate loading are common. In contrast, advanced optical instrumentation provides a robust, high-accuracy alternative that overcomes these limitations.

OPSIS DOAS Gas Analysis

The OPSIS Differential Optical Absorption Spectroscopy (DOAS) system enables continuous, multi-gas monitoring for key smelter emissions including HF, SO₂, NOx, and VOCs. The system provides real-time measurement across long optical paths, enabling accurate quantification of stack, duct, and ambient air emissions without sample extraction. OPSIS DOAS is particularly effective in detecting fugitive releases and validating compliance with environmental standards.

Additionally, OPSIS offers fenceline monitoring systems that provide perimeter-based air quality surveillance. These systems help detect and track emissions beyond the facility boundary, supporting environmental impact assessments and community health protection.

There are multiple reasons for choosing OPSIS as supplier of systems for gas analysis. Among the key benefits of the methods and solutions offered by OPSIS are:

Link is for a variety of short informational videos found on the OPSIS website : OPSIS Play

Contact us for more information

Sales is restricted to the province of Quebec and the Maritime Provinces.

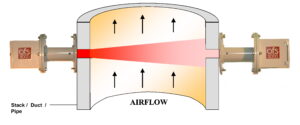

Optical Scientific, Inc. (OSI) optical scintillation anemometry offers a non-intrusive, path-integrated method for measuring airflow and emissions in large ducts and open pot room environments. It is ideally suited for high-temperature, dusty, and chemically aggressive conditions. OSI systems deliver real-time data with high resolution, minimal signal degradation, and low maintenance requirements—making them a dependable choice for continuous ventilation and emissions monitoring in very difficult and demanding environments.

For more information refer to our product page: Optical Scintillation

BinMaster 3D Level Scanner for Alumina Powder Measurement in Aluminum Smelters

Accurate inventory measurement of alumina powder is critical in aluminum smelters to ensure efficient process control, optimize raw material usage, and maintain consistent production rates. Alumina is a fine, dusty, and often highly aerated powder that presents unique challenges for conventional level measurement technologies, especially in large, wide silos with uneven material surfaces, sloping piles, and buildup on walls.

The BinMaster 3D Level Scanner is specifically designed to address these challenges by using low-frequency acoustic mapping technology to generate a precise three-dimensional profile of the material surface inside the silo. Unlike single-point level sensors, which only provide a snapshot of the material height at one location, the 3D scanner captures multiple measurement points across the entire surface. This allows it to calculate not only the highest, lowest, and average levels, but also a more accurate estimate of the total volume of alumina in storage.

Key features and benefits of the BinMaster 3D system include:

• True volume-based inventory measurement – essential for bulk material management and procurement planning.

• Reliable performance in dusty, noisy, and high-temperature environments typical of smelters.

• Detection of surface irregularities and cone-down/cone-up conditions, which are common with aerated alumina.

• Non-contact technology that minimizes maintenance and operational disruptions.

The BinMaster MVL system integrates two or more 3D sensors and is designed for large storage silos containing bulk solids like alumina, clinker, or coal. It combines multiple 3D level sensors strategically mounted on a single silo to map material surfaces with complex topography, such as uneven filling, cone-up or cone-down patterns, and sidewall buildup. By aggregating data from each sensor, the MVL system provides a highly accurate calculation of volume and mass in very wide storage silos.

For more product details and videos : BinMaster 3D

Please contact us at controls@cancoppas.com or call us at the appropriate office should you require additional assistance.

Contact Us